Bucket

Buckets play a crucial role in conveying systems across various industries, aiding in the transportation of materials from one point to another. Here's an overview of types, materials, designs, configurations, and applications of buckets in conveying systems

Types of Buckets

Centrifugal Discharge Bucket

Designed for high-speed applications. Material is discharged using centrifugal force. Commonly used in mining and aggregate industries.

Continuous Discharge Buckets

Designed for slow to moderate-speed applications. Material is continuously discharged by gravity. Used in industries where a steady flow of material is required.

Positive Discharge Buckets

Designed for vertically lifting materials. Controlled discharge using mechanical or hydraulic systems. Common in vertical conveyors for bulk materials.

Low-Profile Buckets

Designed for low headroom applications. Compact design for efficient space utilization.

Deep High-Capacity Buckets

Used for conveying materials with higher volumes. Deeper bucket design for increased capacity.

Materials

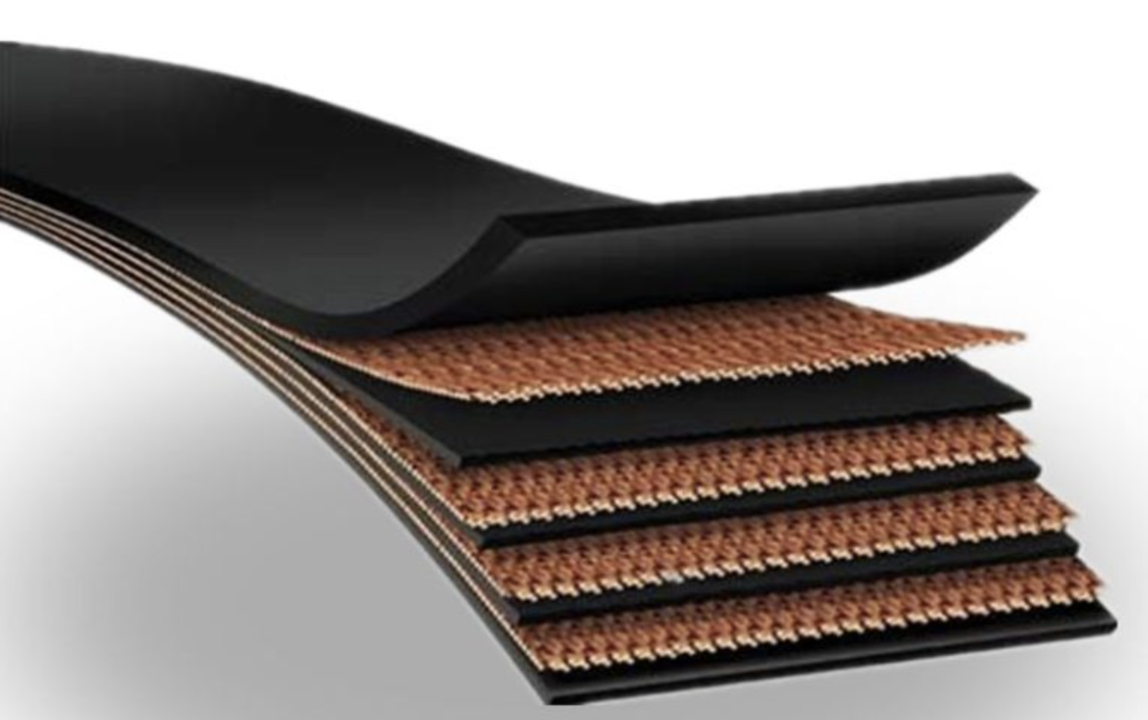

Rubber elevator belts are designed to withstand harsh operating conditions and heavy loads. The combination of high-quality rubber compounds and reinforced carcass structures contributes to their durability. The resistance to wear and abrasion is crucial, especially in industries where the conveyed materials can be abrasive.

Plastic Buckets

Lightweight and corrosion-resistant. Commonly used in food processing and pharmaceutical industries.

Metal Buckets

Durable and suitable for heavy-duty applications. Common metals include steel and stainless steel. Used in industries like mining, Cement & construction.

Nylon Buckets

High strength and abrasion resistance. Suitable for conveying abrasive materials.

Bucket Design and Configurations

Shape and Size

Buckets can vary in shape (e.g., square, round) and size based on the material being conveyed.

Bucket Attachments

Some buckets may have additional features like bolt-on cutting edges for improved material cutting.

Venting

Vent holes can be incorporated to prevent vacuum and facilitate smoother material discharge.

Lip Design

The lip of the bucket can be designed to optimize material loading and discharge.

Applications

Agriculture

Used in grain elevators for the vertical movement of grains. Fertilizer handling in agricultural settings.

Mining

Transporting ore and other mining materials. Handling bulk materials in the extraction process.

Manufacturing

Conveying raw materials in production lines. Transporting finished goods in packaging lines.

Bucket Design and Configurations

Shape and Size

Buckets can vary in shape (e.g., square, round) and size based on the material being conveyed.

Bucket Attachments

Some buckets may have additional features like bolt-on cutting edges for improved material cutting.

Venting

Vent holes can be incorporated to prevent vacuum and facilitate smoother material discharge.

Lip Design

The lip of the bucket can be designed to optimize material loading and discharge.

Applications

Agriculture

Used in grain elevators for the vertical movement of grains. Fertilizer handling in agricultural settings.

Mining

Transporting ore and other mining materials. Handling bulk materials in the extraction process.

Manufacturing

Conveying raw materials in production lines. Transporting finished goods in packaging lines.

Construction

Handling aggregates like sand, gravel, and concrete. Transporting construction materials vertically.

Food Processing

Conveying food products in a hygienic manner. Handling ingredients in the production of food items.

Waste Management

Used in conveyor systems for handling waste materials. Transporting recyclable materials.

Understanding the specific requirements of the conveying system and the characteristics of the materials being handled is essential in selecting the appropriate type, material, and design of buckets for optimal performance.

All Products

Our Products

Conveyor Belt

Industrial Rubber Conveyor Belts find use in a wide range of applications in various industries. IEES offers the finest high performance Industrial Conveyor Belts used in transmission, linear

Read More

Rubber Elevator Belt

Rubber elevator belts are essential components in elevators used for vertical transportation of bulk materials such as grains, coal, ore, and other products. These belts play a crucial role

Read More

Rollers and Idlers

Rollers and idlers play a crucial role in conveyor systems, providing support, guiding movement, and ensuring the efficient and reliable transportation of materials.

Read More

Conveyor System

Conveyor systems are mechanical handling equipment that moves materials from one location to another. They play a crucial role in various industries, such as manufacturing

Read More

Apron Feeders

Apron feeders are engineered to provide robust and dependable material handling solutions for industries requiring the transportation of heavy and abrasive materials.

Read More

Deep Pan Conveyor

Deep pan conveyors consist of a continuous chain with flights (metal plates) that move through an enclosed trough. The chain is submerged in the material being conveyed

Read More