Conveyor Systems

Conveyor systems are mechanical handling equipment that moves materials from one location to another. They play a crucial role in various industries, such as manufacturing, distribution, packaging, and logistics. Different types of conveyor systems are designed to meet specific material handling needs. Here's an overview of some common conveyor system types, integration with other components, customization options, and efficiency benefits:

Conveyor System Types

Belt Conveyors

Description: Consist of a continuous belt that moves over a series of rollers or pulleys. Used for horizontal, inclined, or declined transportation of goods.

Applications: Ideal for transporting bulk materials, packages, and irregularly shaped items.

Roller Conveyors

Description: Utilize rollers mounted on a series of frames to move items. Can be powered or gravity-driven.

Applications: Suitable for moving heavier items or pallets. Gravity roller conveyors are often used for accumulation.

Chain Conveyors

Description: Use a chain to move items along a path of fixed or adjustable tracks.

Applications: Commonly used for moving heavy loads, such as pallets or large containers.

Slat Conveyors

Description: Consist of slats or plates linked together to form a moving surface. Can be flat or articulated.

Applications: Effective for carrying heavy loads or items with irregular shapes.

Screw Conveyors

Description: Feature a helical screw that rotates to move materials along a trough.

Applications: Used for conveying bulk materials, especially powders and granules.

Integration with Other Components

Sensors

Used for detecting the presence of items on the conveyor, enabling automation and precise control.

Control Systems

PLCs (Programmable Logic Controllers) and other control systems manage the conveyor's operation, ensuring synchronization with other processes.

Sorting and Diverting Devices

Enable the diversion of items to different conveyor lines based on predefined criteria.

Barcode Scanners and RFID Systems

Used for tracking and identifying items on the conveyor for efficient sorting and routing.

Customization Options and System Design

Conveyor Length and Width

Tailored to specific facility layouts and material handling requirements.

Belt Type and Material

Selection based on the nature of the transported items (e.g., smooth, cleated, rubber, plastic).

Drive Systems

Options include electric motors, gearboxes, and variable frequency drives for speed control.

Frame and Structure

Customizable materials and designs to accommodate different loads and environmental conditions.

Efficiency and Productivity Benefits

Increased Throughput

Conveyor systems enable continuous, automated material flow, enhancing overall productivity.

Reduced Labor Costs

Automation reduces the need for manual material handling, leading to cost savings and increased efficiency.

Improved Safety

Minimizes manual handling risks, promoting a safer working environment.

Space Utilization

Conveyors are designed to optimize floor space, allowing for more efficient use of available areas.

Flexibility and Scalability

Modular designs allow for easy system expansion or reconfiguration to adapt to changing production needs.

In summary, conveyor systems play a vital role in streamlining material handling processes across various industries, providing efficiency, flexibility, and customization options to meet specific operational requirements. The integration with other components enhances automation and control, contributing to overall productivity gains.

All Products

Our Products

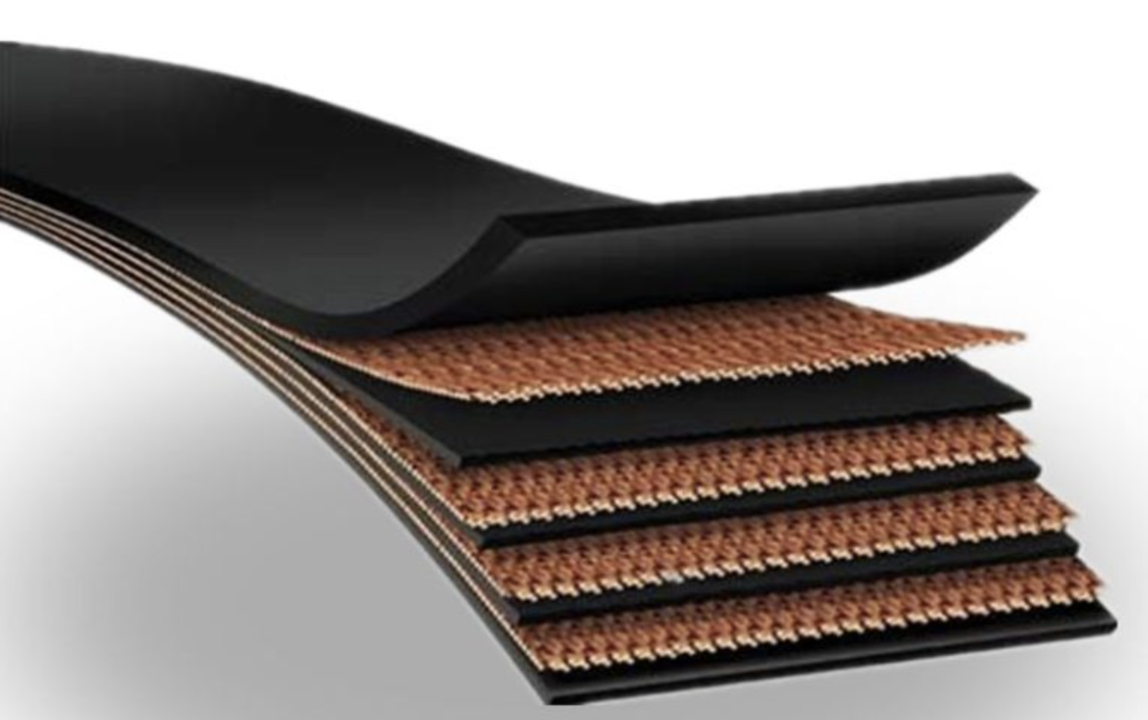

Conveyor Belt

Industrial Rubber Conveyor Belts find use in a wide range of applications in various industries. IEES offers the finest high performance Industrial Conveyor Belts used in transmission, linear

Read More

Rubber Elevator Belt

Rubber elevator belts are essential components in elevators used for vertical transportation of bulk materials such as grains, coal, ore, and other products. These belts play a crucial role

Read More

Rollers and Idlers

Rollers and idlers play a crucial role in conveyor systems, providing support, guiding movement, and ensuring the efficient and reliable transportation of materials.

Read More

Conveyor System

Conveyor systems are mechanical handling equipment that moves materials from one location to another. They play a crucial role in various industries, such as manufacturing

Read More

Apron Feeders

Apron feeders are engineered to provide robust and dependable material handling solutions for industries requiring the transportation of heavy and abrasive materials.

Read More

Deep Pan Conveyor

Deep pan conveyors consist of a continuous chain with flights (metal plates) that move through an enclosed trough. The chain is submerged in the material being conveyed

Read More