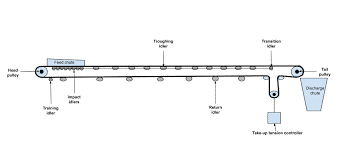

Rollers and Idlers

Rollers and idlers play a crucial role in conveyor systems, providing support, guiding movement, and ensuring the efficient and reliable transportation of materials. Here's an overview of their role, types, material options, durability, and maintenance considerations.

Support and Guidance

Rollers and idlers support the conveyor belt and help guide it along the conveyor structure. They prevent sagging, misalignment, and excess friction, ensuring smooth and efficient material transport.

Reduced Friction

Rollers and idlers reduce the friction between the conveyor belt and the supporting structure, minimizing wear and tear on both components.

Belt Tracking

Idlers are essential for maintaining proper belt tracking, ensuring that the conveyor belt stays aligned and centered on the conveyor frame.

Impact Absorption

Some rollers are designed to absorb impact from heavy or sharp materials, protecting the conveyor belt and extending its lifespan.

Types of Rollers and Idlers

Troughing Idlers

Designed to support the conveyor belt in a troughed configuration, enhancing the belt's carrying capacity.

Return Idlers

Positioned on the underside of the conveyor to support the return run of the belt.

Impact Idlers

Absorb and reduce the impact of large, heavy, or sharp materials on the conveyor belt.

Training Idlers

Adjustments to help maintain proper belt alignment and prevent off-tracking.

Steel Rollers

Commonly used for heavy-duty applications due to their durability and load-bearing capacity.

Plastic Rollers

Lightweight and corrosion-resistant, suitable for applications where weight is a concern.

Rubber-Coated Rollers

Provide additional grip and reduce slippage, particularly useful in incline or decline conveyor systems.

Material Options and Durability

Steel

Known for its strength and durability, making it suitable for heavy-duty applications.

Aluminum

Lightweight and corrosion-resistant, ideal for applications where weight is a critical factor.

Plastic

Offers corrosion resistance and is suitable for applications where weight is a concern.

Rubber

Used for coating rollers to improve grip and reduce slippage.

Maintenance and Replacement Considerations

Regular Inspection

Periodic inspection of rollers and idlers to identify signs of wear, misalignment, or damage.

Lubrication

Some types of rollers may require lubrication to reduce friction and extend their lifespan.

Timely Replacement

Replace rollers and idlers as soon as signs of excessive wear or damage are detected to prevent further damage to the conveyor system.

Alignment

Ensure proper alignment of rollers and idlers to prevent belt tracking issues.

Training

Proper training of personnel for maintenance tasks, including replacement procedures and safety protocols.

In conclusion, rollers and idlers are integral components of conveyor systems, providing support, guidance, and impact absorption. The choice of material, regular maintenance, and timely replacement are essential for ensuring the longevity and efficiency of conveyor systems.

All Products

Our Products

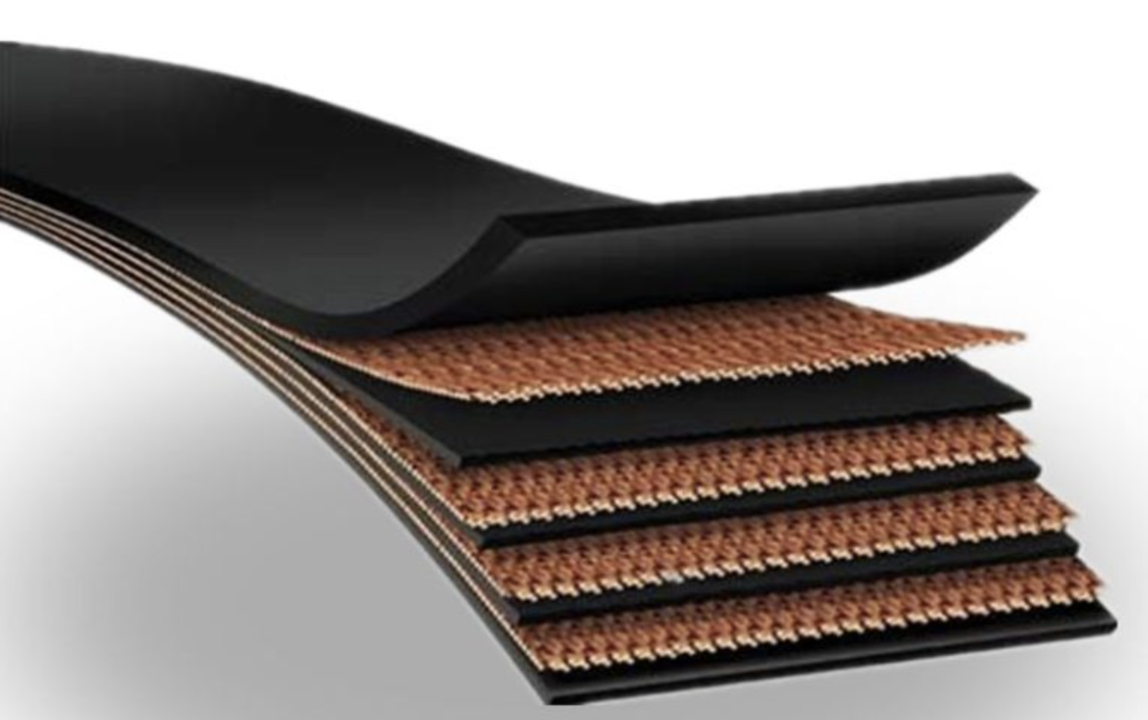

Conveyor Belt

Industrial Rubber Conveyor Belts find use in a wide range of applications in various industries. IEES offers the finest high performance Industrial Conveyor Belts used in transmission, linear

Read More

Rubber Elevator Belt

Rubber elevator belts are essential components in elevators used for vertical transportation of bulk materials such as grains, coal, ore, and other products. These belts play a crucial role

Read More

Rollers and Idlers

Rollers and idlers play a crucial role in conveyor systems, providing support, guiding movement, and ensuring the efficient and reliable transportation of materials.

Read More

Conveyor System

Conveyor systems are mechanical handling equipment that moves materials from one location to another. They play a crucial role in various industries, such as manufacturing

Read More

Apron Feeders

Apron feeders are engineered to provide robust and dependable material handling solutions for industries requiring the transportation of heavy and abrasive materials.

Read More

Deep Pan Conveyor

Deep pan conveyors consist of a continuous chain with flights (metal plates) that move through an enclosed trough. The chain is submerged in the material being conveyed

Read More