Rubber Elevator Belt

Rubber elevator belts are essential components in elevators used for vertical transportation of bulk materials such as grains, coal, ore, and other products. These belts play a crucial role in ensuring smooth and efficient material handling in various industries. Here are some features, benefits, common applications, and technical specifications of rubber elevator belts:

Features and Benefits

Industrial Rubber Conveyor Belts find use in a wide range of applications in various industries. IEES offers the finest high performance Industrial Conveyor Belts used in transmission, linear positioning, conveying and rotary positioning.

1. Material Composition

Rubber elevator belts are typically made from high-quality rubber compounds. The rubber provides flexibility, strength, and resistance to abrasion, ensuring long-lasting performance.

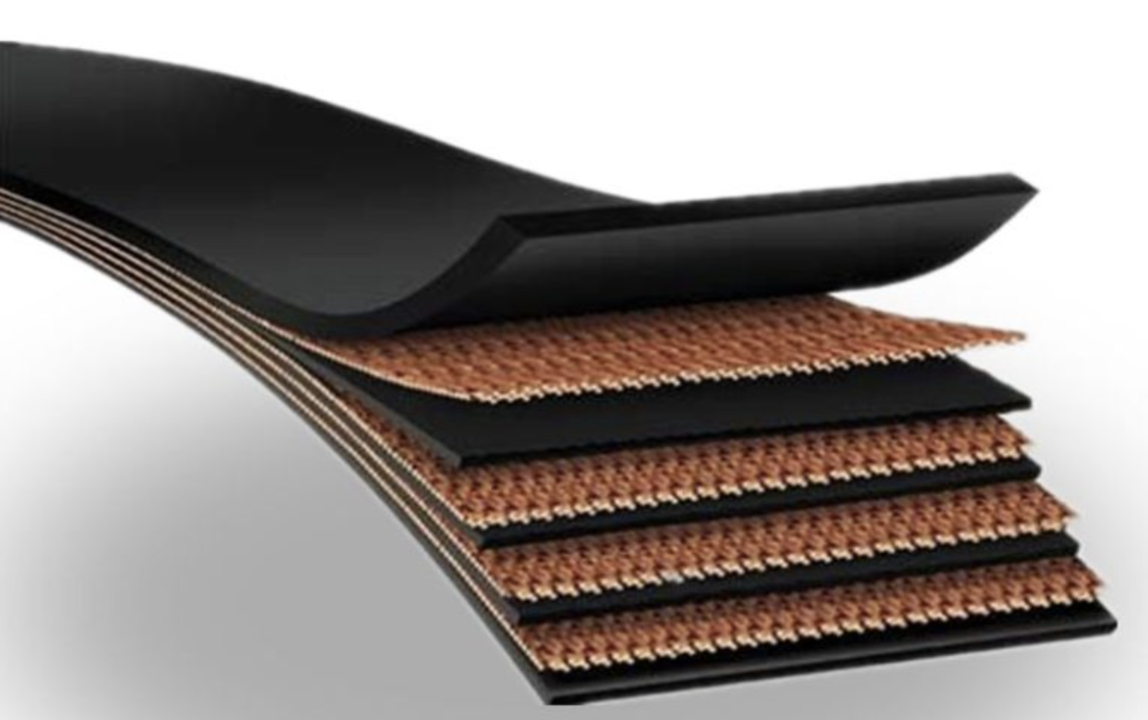

2. Carcass Structure

The belts often feature a multi-ply construction for added strength and durability. The carcass layers contribute to the overall load-bearing capacity and impact resistance of the belt.

3. Bucket Attachment

Rubber elevator belts usually have buckets attached to them, which are used to carry the bulk material. The bucket attachment is designed to securely hold and transport materials without spillage.

4. Oil and Chemical Resistance

Many rubber elevator belts are resistant to oil and various chemicals, enhancing their performance in industries where exposure to such substances is common.

5. High Tensile Strength

Rubber elevator belts are engineered to have high tensile strength, allowing them to withstand the vertical and horizontal forces encountered during material transportation.

6. Low Stretch

These belts often exhibit low elongation, ensuring minimal stretch during operation. This characteristic is crucial for maintaining the proper tension and alignment in the elevator system.

7. Smooth Operation

The rubber surface of the elevator belt contributes to smooth material discharge, preventing jams and ensuring a continuous flow of materials.

Common Applications and Industries:

1. Agriculture

Used for elevating grains, seeds, and other agricultural products in grain elevators and processing facilities.

2. Mining

Employed in mines to transport ores and minerals vertically from one level to another.

3. Power Plants

Used in coal-fired power plants to handle and transport coal from storage to various processing points.

4. Cement Industry

Utilized for the vertical transport of raw materials such as limestone, clay, and shale in cement plants.

5. Food Processing

Applied in the food industry for conveying bulk food products like grains, seeds, and sugar.

Durability and Wear Resistance

Rubber elevator belts are designed to withstand harsh operating conditions and heavy loads. The combination of high-quality rubber compounds and reinforced carcass structures contributes to their durability. The resistance to wear and abrasion is crucial, especially in industries where the conveyed materials can be abrasive.

Technical Specifications and Customization Options

Rubber elevator belts are designed to withstand harsh operating conditions and heavy loads. The combination of high-quality rubber compounds and reinforced carcass structures contributes to their durability. The resistance to wear and abrasion is crucial, especially in industries where the conveyed materials can be abrasive.

1. Belt Width and Thickness

Available in various widths and thicknesses to suit different elevator systems and applications.

2. Ply Rating

The number of layers or plies in the belt affects its strength and load-carrying capacity.

3. Tensile Strength

Specified to indicate the maximum force the belt can withstand without breaking.

4. Elongation

Indicates the amount of stretch the belt may experience during operation.

5. Temperature Resistance:

Some belts are designed to operate in extreme temperatures, ensuring performance in hot or cold environments.

6. Oil and Chemical Resistance Ratings

Depending on the application, elevator belts may be customized to resist specific chemicals and oils.

7. Bucket Design

The shape and material of the buckets attached to the belt can be customized based on the nature of the material being transported.

When selecting a rubber elevator belt, it's important to consider the specific requirements of the application, including the type of material being transported, the operating environment, and the desired performance characteristics. Regular maintenance and proper tensioning are also essential for maximizing the lifespan and efficiency of rubber elevator belts.

Rubber Elevator Belt

Rubber Elevator Belt

Elevator Belt Fastener

All Products

Our Products

Conveyor Belt

Industrial Rubber Conveyor Belts find use in a wide range of applications in various industries. IEES offers the finest high performance Industrial Conveyor Belts used in transmission, linear

Read More

Rubber Elevator Belt

Rubber elevator belts are essential components in elevators used for vertical transportation of bulk materials such as grains, coal, ore, and other products. These belts play a crucial role

Read More

Rollers and Idlers

Rollers and idlers play a crucial role in conveyor systems, providing support, guiding movement, and ensuring the efficient and reliable transportation of materials.

Read More

Conveyor System

Conveyor systems are mechanical handling equipment that moves materials from one location to another. They play a crucial role in various industries, such as manufacturing

Read More

Apron Feeders

Apron feeders are engineered to provide robust and dependable material handling solutions for industries requiring the transportation of heavy and abrasive materials.

Read More

Deep Pan Conveyor

Deep pan conveyors consist of a continuous chain with flights (metal plates) that move through an enclosed trough. The chain is submerged in the material being conveyed

Read More